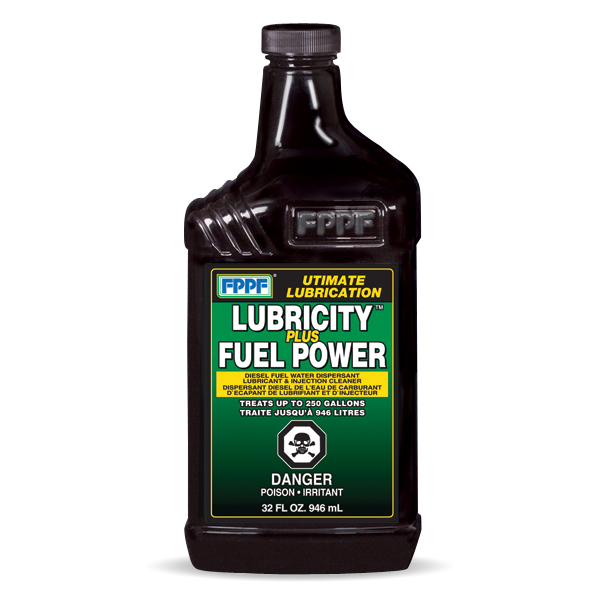

fuel additive Company

The Importance of Fuel Treatment for Optimal HVAC Performance

Maintaining the optimal performance of your HVAC system is essential to ensure the comfort of your home or office space. However, many people overlook the importance of fuel treatment as a critical component of HVAC maintenance. Fuel treatment is adding additives to the fuel used by your HVAC system to remove contaminants, protect against corrosion, and improve combustion efficiency. Neglecting fuel treatment can lead to reduced performance, higher energy bills, and even damage to your equipment. In this blog post, we will explore the importance of fuel treatment for optimal HVAC performance, discussing its benefits and how it can help you maintain a comfortable and efficient living or working environment.

The Science of Fuel Treatment: How It Impacts HVAC Performance

The performance of an HVAC system is a crucial factor in maintaining a comfortable and safe indoor environment. One often overlooked aspect of HVAC performance is the quality of the fuel used to power the system. Fuel treatment is critical in ensuring the smooth operation of HVAC equipment and preventing costly repairs.

The Science Behind Fuel Treatment

Fuel treatment removes impurities, contaminants, and water from the fuel before it is used in HVAC equipment. It is essential to remove these elements because they can clog filters, cause corrosion, and decrease energy efficiency. The most common contaminants found in fuel include water, dirt, and microbial growth.

Fuel treatment chemicals break down these contaminants into smaller particles that can be filtered out or burned off. They also work to prevent future contamination by neutralizing acids and dispersing water. Fuel treatment aims to ensure that the fuel used in HVAC equipment is clean, stable, and free of contaminants that could negatively impact performance.

How Fuel Treatment Can Improve the Efficiency of Your HVAC System

Fuel treatment is a crucial aspect of HVAC maintenance that can significantly improve the efficiency of your HVAC system. HVAC systems use a variety of fuels, such as natural gas, propane, and oil, which can contain impurities and contaminants that reduce the system’s efficiency.

Removal of Contaminants

The most significant advantage of fuel treatment is that it removes contaminants from the fuel, such as dirt, water, and microbial growth, which can reduce the system’s efficiency. Contaminants can clog fuel lines, valves, and burners, making it difficult for the HVAC system to operate efficiently. Fuel treatment removes these impurities from the fuel, allowing it to flow more easily through the system and increasing efficiency.

Protection against Corrosion

Fuel treatment can also protect your HVAC system from corrosion, damaging the system’s components and reducing its efficiency. Corrosion occurs when moisture and oxygen react with metal surfaces, causing them to degrade. Fuel treatment can remove water from the fuel, preventing corrosion and protecting the HVAC system’s components.

Improved Combustion

Fuel treatment can improve combustion by making fuel burn more efficiently, reducing waste, and increasing efficiency. Fuel additives can help break down the fuel into smaller, more combustible particles, allowing it to burn more efficiently and produce more heat. Improved combustion can also reduce emissions and improve indoor air quality.

Better Maintenance

Fuel treatment can also improve the efficiency of your HVAC system by reducing the need for maintenance. By removing contaminants and preventing corrosion, fuel treatment can help reduce wear and tear on the system’s components, extending its lifespan and reducing the need for repairs and maintenance.

Fuel Treatment and Indoor Air Quality: The Connection You Need to Know

Indoor air quality is essential to the health and comfort of building occupants. Poor indoor air quality can lead to respiratory problems, allergies, and other health issues. One factor that can impact indoor air quality is the fuel used to power HVAC systems.

Fuel Contaminants and Indoor Air Quality

The fuel used in HVAC systems can contain contaminants that impact indoor air quality. These contaminants can include dirt, water, and microbial growth, accumulating in the fuel tank and lines. When the HVAC system runs, these contaminants can be released into the air, reducing indoor air quality.

Contaminants can also lead to the buildup of pollutants in the HVAC system, including soot, carbon monoxide, and nitrogen oxides. These pollutants can cause respiratory problems, headaches, and other health issues, particularly in vulnerable populations such as children and the elderly.

Fuel Treatment and Indoor Air Quality

Fuel treatment can improve indoor air quality by removing contaminants from the fuel before it enters the HVAC system. Fuel treatment can also prevent the buildup of pollutants in the system, reducing the number of pollutants released into the air. Fuel treatment can improve indoor air quality and reduce the risk of health problems by removing contaminants and reducing the buildup of pollutants.

Fuel treatment can also improve combustion efficiency, reducing the fuel needed to heat or cool a building. Improved combustion can also reduce the emission of pollutants, further improving indoor air quality.

Fuel Treatment and the Environment: The Positive Impact on the Planet and Your HVAC

HVAC systems can significantly impact the environment, from the emissions produced during operation to the resources needed to manufacture and maintain the systems. One way to reduce the environmental impact of HVAC systems is through fuel treatment. These are some of the impacts fuel treatments have on the planet:

- Reduced Emissions: Fuel treatment can reduce the emissions produced by HVAC systems, improving air quality and reducing the impact on the planet. By removing contaminants from the fuel, fuel treatment can improve combustion efficiency, reducing the fuel needed to heat or cool a building. Improved combustion efficiency also reduces the emission of pollutants such as carbon monoxide and nitrogen oxides.

- Reduced Energy Consumption: Fuel treatment can also reduce energy consumption, reducing the environmental impact of HVAC systems. By improving combustion efficiency, fuel treatment can reduce the fuel needed to operate the system, reducing energy consumption and greenhouse gas emissions.

- Extended HVAC Lifespan: Fuel treatment can also extend the lifespan of HVAC systems, reducing the need for replacement and the resources needed to manufacture and install new systems. By removing contaminants and protecting against corrosion, fuel treatment can minimize wear and tear on the system’s components, extending its lifespan and reducing the need for repairs and replacement.

- Reduced Waste: Fuel treatment can also reduce waste by reducing the need for maintenance and repairs. By preventing the buildup of contaminants and protecting against corrosion, fuel treatment can reduce the need for maintenance and repairs, reducing the amount of waste generated by HVAC systems.

Choosing the Right Fuel Treatment for Your HVAC: Factors to Consider

Fuel treatment is essential to maintaining your HVAC system, ensuring efficient performance, and extending the lifespan of your equipment. However, with so many fuel treatment options available, knowing which one is right for your HVAC system can be challenging. These are some of the factors to consider when choosing the right fuel treatment for your HVAC:

- Type of Fuel: The type of fuel used by your HVAC system is crucial in selecting the right fuel treatment. Different fuel treatments are designed to work with specific fuel types, and using the wrong one can lead to reduced effectiveness or even damage to your equipment. Make sure to select a fuel treatment that is compatible with the fuel type used by your HVAC system.

- Contaminant Removal: The primary purpose of fuel treatment is to remove contaminants from the fuel used by your HVAC system. Different fuel treatments are designed to remove different types of contaminants, so selecting one that addresses the specific contaminants present in your fuel is essential. Common contaminants include water, dirt, and microbial growth.

- Corrosion Protection: Corrosion is another issue that can impact the performance and lifespan of your HVAC system. Some fuel treatments are designed to protect against corrosion, while others do not provide this benefit. If corrosion concerns your HVAC system, choose a fuel treatment with corrosion protection.

- Efficiency Improvement: Some fuel treatments are designed to improve combustion efficiency, reducing the fuel needed to heat or cool your building. Improved combustion efficiency can result in lower energy bills and reduced greenhouse gas emissions. If you want to improve your HVAC system’s efficiency, choose a fuel treatment that includes this feature.

- Manufacturer Recommendations: It’s essential to consider the manufacturer’s recommendations for your HVAC system. Some manufacturers may have specific fuel treatment recommendations, and using a different product could void your warranty. Check with the manufacturer or consult an HVAC professional to ensure you are selecting a fuel treatment that meets their specifications.

Conclusion

In conclusion, fuel treatment is a critical component of HVAC maintenance that should not be overlooked. Using fuel treatment additives can remove contaminants, protect against corrosion, and improve combustion efficiency, resulting in optimal HVAC performance. Neglecting fuel treatment can lead to reduced performance, increased energy bills, and even damage to your equipment. FPPF Chemical Company offers a wide range of fuel treatment products designed to meet the unique needs of your HVAC system. So, don’t overlook the importance of fuel treatment for optimal HVAC performance, and contact FPPF Chemical Company today to learn more about their products.