fuel additive Company

Diesel Engine SCR & DPF Regen Systems and How to Treat with Premium Fuel Additives

FPPF remains at the forefront of fuel additive technology. All FPPF products are formulated to function effectively and actually enhance the operation of all the latest diesel engine technologies, including common rail, ERG, DPF and SCR.

There are increasing concerns regarding the operation of diesel engines with SCR and DPF systems when used with quality fuel additives. Some fuel additives claim to improve the efficiency of both the DPF and the SCR systems on new trucks. We here at FPPF would like to investigate this further.

Two Diesel Fuel Systems

- DPF (diesel particulate filter) is the technology that incorporates the high-tech filtering/regen processes to remove most solid carbon-based emissions from fuel exhaust. (The regen process is a costly self-cleaning of the system requiring downtime.) There are several different filtering methods and a variety of filtering media employed but the intended result is constant: fewer emissions. The actual success results vary from 35% to over 99%.

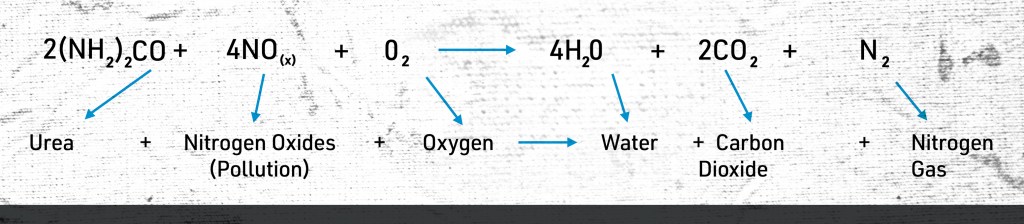

- SCR (selective catalytic reduction) systems are the newest addition to diesel engine technology. This system uses DEF (diesel exhaust fluid)—a urea/water-based fluid that removes nitrogen oxides from exhaust gases before exiting the vehicle. The SCR technology enables trucks to meet the new “Tier 4” emission standards that make vehicle exhaust almost as clean (or cleaner) than the air entering the vehicle.

The Chemistry Involved

One of the biggest concerns is what effects (if any) do fuel additives have on the operation enhancement of these two systems.

All FPPF fuel additives assist in the proper and efficient operation of both SCR and DPF pollution abatement systems.

What Is Crude Oil?

It’s important to remember crude oil is primarily a mixture of decaying plant and animal life millions of years old. Diesel fuel is a middle distillate of crude oil and consists of a variety of over 150 different components making the polluting potential of every batch of fuel different. The U.S. has the highest diesel engine emission standards in the world, but fuel quality issues prevent universal compliances with these standards. In fact, the quality of some starting crude oil today in the worst it’s ever been. This is due in part to a depleting supply of sweet light crude oil and replacing it with Canadian tar sand crudes and shale oil crudes. Today’s improved refining techniques allow fuel producers to successfully use these crudes for production of gasoline, diesel, plastic and a variety of other products.

Know How to Treat Modern Diesel Fuels

New fuels are prone to more rapid degradation and instability which causes increased fuel-related deposits and poor combustion. This can lead to DPF issues, increased smoke and higher unwanted emissions, especially if the DPF and SCR systems are not working properly.

The irony is that today’s fuels contain almost no sulfur, but can actually be more detrimental to the environment in other ways were it not for new engine technology. Modern diesel fuels tend to hold more moisture, increasing the presence of naturally occurring salts. These can lead to injector deposits and improper injection operation.

Small Components Create Big Problems

Modern engine fuel systems are manufactured with special fuel delivery components that require constant, sophisticated efforts to ensure good working order. The diesel fuel pumps associated with these systems create enormously high operating fuel pressures and the exceptionally fine fuel injector holes and tolerances are extremely sensitive to even the slightest amount of dirt, debris, moisture and other potential contaminants typically found in diesel fuel. So if they’re not kept in clean working order, these systems will lead to exponential operational issues as well the creation of unburned hydrocarbon emissions at all levels of operation.

Know the New Regen Systems

New DPF regen systems actually use the vehicle’s diesel fuel as a cleaning agent during the regen process. This is why it is critical that only fuel additives with strong detergency and Tier 4 compliance be used. (Tier 4 contains the new emission standards for common rail engines.) FPPF Diesel Injector Cleaner and Super Fuel Stabilizer are designed to be used with common rail injectors and meet all Tier 4 criteria. The same active ingredients in these products are contained in other premium FPPF diesel fuel additives at lower concentrations. These active ingredients chemically break down microscopic pollutants and assist the functionality of DPF and SCR systems.

Since diesel fuel is used as the cleaning agent during DPF regens, increased DPF regen frequency results in increased fuel consumption without any additional horsepower or work accomplished.

Other diesel fuel physical parameters that impact DPF regens and exhaust emissions are the fuel distillation range (IBP—initial boiling point and other boiling temperatures including the end point temperature), engine cetane number and the HFRR fuel lubricity value.

FPPF fuel additives also significantly improve fuel lubricity and cetane numbers. FPPF Lubricity Plus Fuel Power, 8+ Cetane Improver, Total Power and other FPPF premium additives enhance the operation of DPF systems and reduce the need for system regenerations in warm and cold weather conditions.

Cold Weather System Reactions

Diesel fuel thickens as the temperature drops. And each fuel reacts differently to cold weather. Fuel gelling is a function of the chemical makeup of fuel. When wax crystals form in fuel without an effective anti-gel, not only can they prevent the operation of your vehicle but they can also affect the DPF and EGR systems. These wax crystals agglomerate and foul the fuel system, (pumps, filters and injectors) causing poor or incomplete combustion which increases unburned hydrocarbon emissions.

The poor combustion efficiency leads to an increased number of carbon particulates entering the EGR valve and DPF systems which increases the need for DPF regeneration. It also increases your diesel fuel consumption with no additional horsepower sent to the drive train.

How FPPF Provides a Solution

All the issues affecting diesel fuel combustion efficiency and unburned diesel fuel hydrocarbon emissions can be eliminated by treating your diesel fuel with FPPF premium fuel additives.

Using FPPF Diesel Injector Cleaner, 8+ Cetane Improver, Super Fuel Stabilizer or any of the FPPF combination (multi-functional) additives including Lubricity Plus Fuel Power, Total Power, Polar Power, Agri Fuel Treatment and more greatly enhances the performance of the latest diesel engine emission reduction technology systems and reduces the need for regenerations of your system.